Introduction:

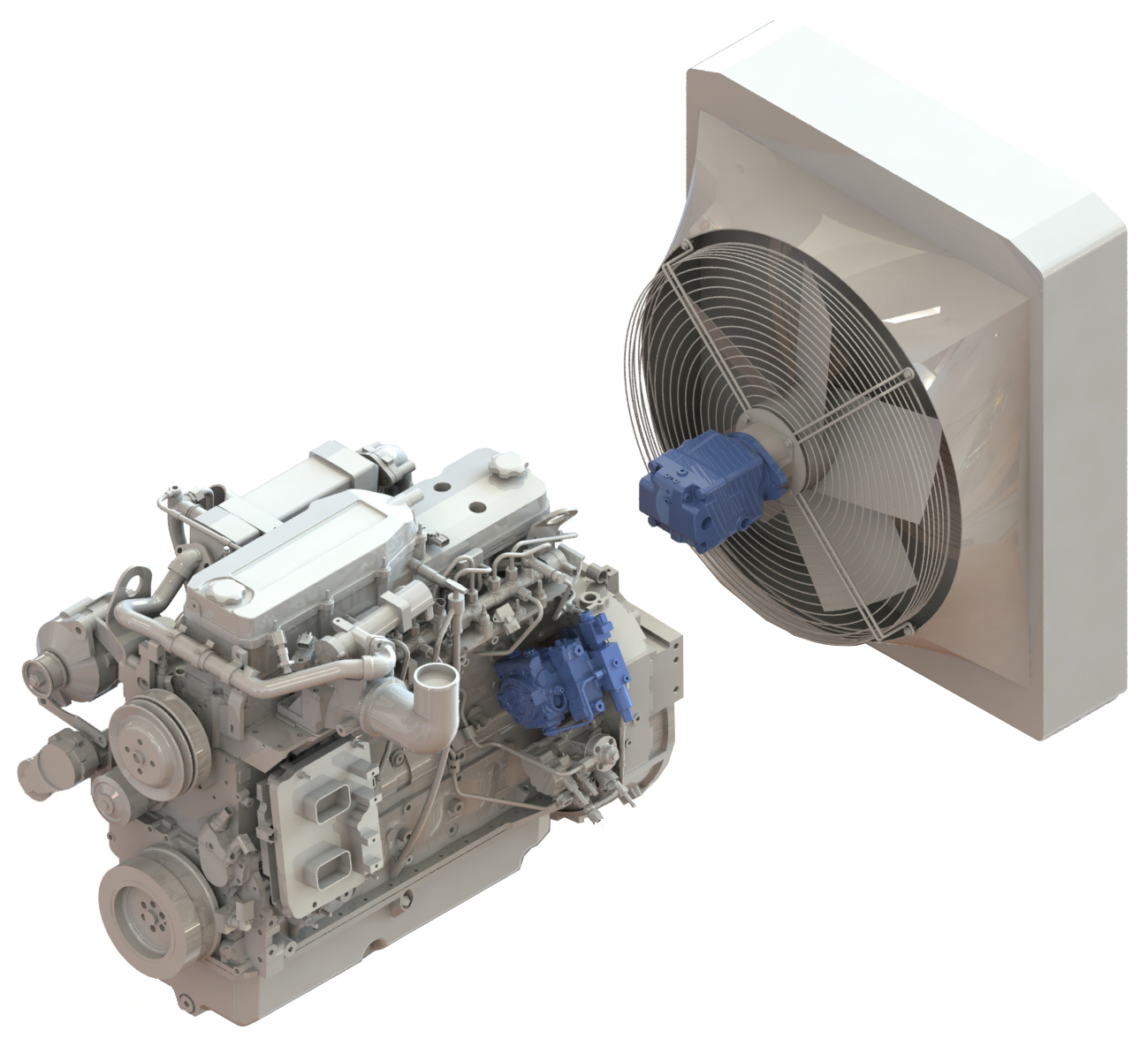

In the ever-evolving landscape of industrial technology, advancements that enhance efficiency and sustainability are highly sought after. One such breakthrough making waves in various sectors is the innovative Fan Drive System, designed to optimize operations in both closed loop and open loop environments. Let’s delve into the intricacies of this cutting-edge technology and its potential impact on industrial processes.

Fan Drive System Overview:

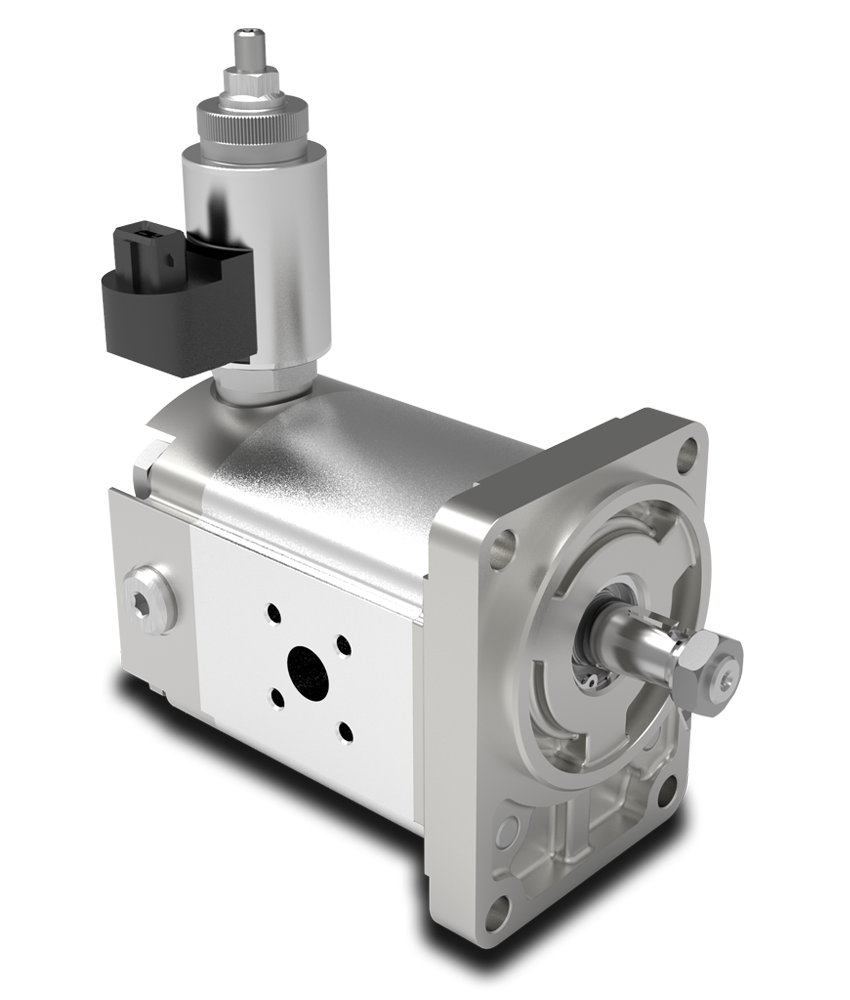

The Fan Drive System represents a leap forward in the realm of fluid power and control. Essentially, it is a hydraulic system designed to efficiently drive and control fans in industrial applications. This technology is particularly versatile, finding applications in both closed loop and open loop systems.

- Closed Loop Efficiency:

In closed loop systems, the Fan Drive System operates in a circuit where hydraulic fluid is circulated between the pump and the motor. This closed-loop configuration allows for precise control of fan speed, resulting in optimal energy consumption. The Fan Drive System’s ability to modulate fan speed based on real-time requirements not only ensures energy efficiency but also contributes to the overall longevity of the equipment.

Technical datasheet: CLICK HERE

- Open Loop Adaptability:

The adaptability of the Fan Drive System extends to open loop configurations, where fluid is discharged after passing through the motor. The system’s versatility allows it to seamlessly integrate into various open loop setups, catering to a wide range of industrial applications. This adaptability is crucial for industries with diverse operational requirements, offering a cost-effective solution without compromising on performance.

Technical datasheet:

Fan Drive System by Kawasaki:

Fan Drive System by Walvoil:

Key Features:

- Energy Efficiency: The Fan Drive System’s ability to precisely control fan speed leads to significant energy savings, making it an environmentally friendly choice for industries striving to reduce their carbon footprint.

- Customization: The system can be tailored to meet specific operational needs, providing a level of customization that enhances its applicability across different industries.

- Reliability: The closed-loop design not only ensures efficiency but also contributes to the overall reliability and durability of the system, reducing maintenance requirements and downtime.

- Remote Monitoring: With the integration of smart technology, Fan Drive Systems can be monitored remotely, allowing for real-time adjustments and preventive maintenance measures.

Applications:

- The Fan Drive System’s applications span across various industries, including but not limited to:

- HVAC Systems: Optimizing the performance of heating, ventilation, and air conditioning systems.

- Industrial Cooling: Enhancing efficiency in cooling systems for manufacturing processes.

- Agricultural Machinery: Improving the energy efficiency of tractors and other farming equipment.

- Renewable Energy: Supporting wind turbines and solar power systems with efficient cooling mechanisms.

Conclusion:

As industries continue to prioritize sustainability and operational efficiency, the Fan Drive System emerges as a game-changer. Its ability to seamlessly integrate into both closed loop and open loop systems, coupled with its energy-efficient design, positions it as a key player in the drive towards a more sustainable industrial future. The Fan Drive System not only optimizes current processes but also sets the stage for a new era of innovation and excellence in fluid power technology.