Forestry machines, such as forestry harvesters, forwarders, and mulchers, are specialized equipment used for various tasks in the forestry industry, including tree harvesting, log transportation, and land clearing. These machines rely heavily on hydraulic systems for their operations due to the need for powerful and precise movements. Here’s a detailed breakdown of the hydraulic components and

their functions in the hydraulic circuit of a forestry machine:

Hydraulic Circuit of a Forestry Machine:

- Hydraulic Pump: The hydraulic pump generates high pressure to power the hydraulic functions of the forestry machine. It draws hydraulic fluid from the reservoir and pressurizes it for distribution.

- Hydraulic Fluid Reservoir: The reservoir stores hydraulic fluid, which is drawn by the pump. It ensures a steady supply of fluid, manages temperature, and helps eliminate air bubbles.

- Control Valves: Forestry machines have multiple control valves that regulate the flow of hydraulic fluid to different components. These valves control movements of the boom, grapple, tracks or wheels, and other attachments.

- Boom and Arm Mechanism: Hydraulic cylinders and valves control the boom and arm of the forestry machine. These components allow the machine to reach and grasp trees, making it possible to harvest or manipulate them.

- Grapple Attachment: Many forestry machines are equipped with grapple attachments to hold and transport logs. Hydraulic cylinders and valves control the grapple’s opening and closing, allowing for efficient log handling.

- Sawing Mechanism: For harvesting trees, some forestry machines have hydraulic sawing mechanisms that cut down trees. These mechanisms can include saw bars, chains, and hydraulic motors.

- Rotating and Tilting Mechanisms: Forestry machines may have hydraulic systems that enable the cab or attachments to rotate and tilt. This flexibility helps operators navigate rough terrain and manipulate trees and logs.

- Log Forwarding: Forwarders, a type of forestry machine, use hydraulic systems to load, carry, and unload logs onto trailers. The hydraulic components control the crane, grapple, and conveyor systems.

- Mulching Attachments: Forestry mulchers, used for land clearing, have hydraulic motors that drive the cutting heads. These motors are powered by the hydraulic system and enable the machine to shred vegetation.

- Stabilization Systems: Some forestry machines have stabilization systems that use hydraulic cylinders to level the machine on uneven terrain, improving safety and efficiency.

- Variable Speed Control: Advanced forestry machines may feature variable speed control systems to adjust the speed and force of hydraulic movements based on the specific task and terrain conditions.

- Hydraulic Fluid Cooling: Hydraulic fluid cooling systems help maintain optimal temperatures during continuous operation, preventing overheating of hydraulic components.

- Safety and Load Sensing: Modern forestry machines often incorporate safety features and load sensing systems that adjust hydraulic power according to the load and terrain, enhancing overall efficiency and safety.

The specific components and functions in the hydraulic circuit of a forestry machine depend on the machine’s type, intended use, and technological advancements. Hydraulic systems play a critical role in providing the power, precision, and flexibility needed for the challenging tasks performed by forestry machines.

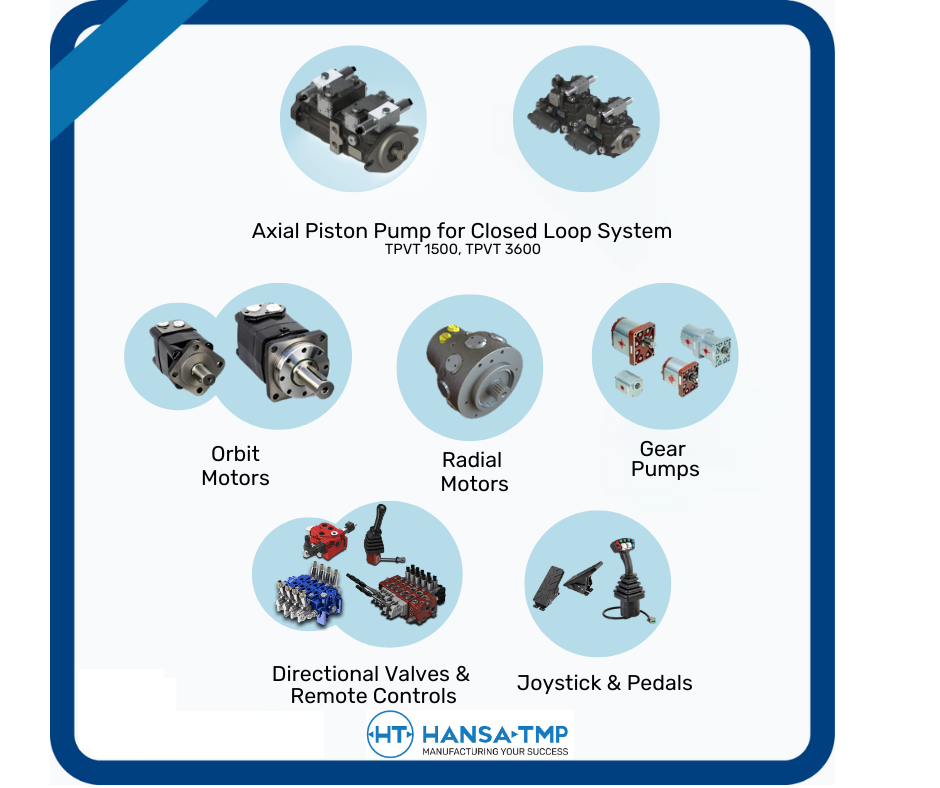

The benefits of the system proposed by HANSA TMP are manifold:

- Compactness

- Reliability

- Reduced consumption

- A single partner for hydraulics components

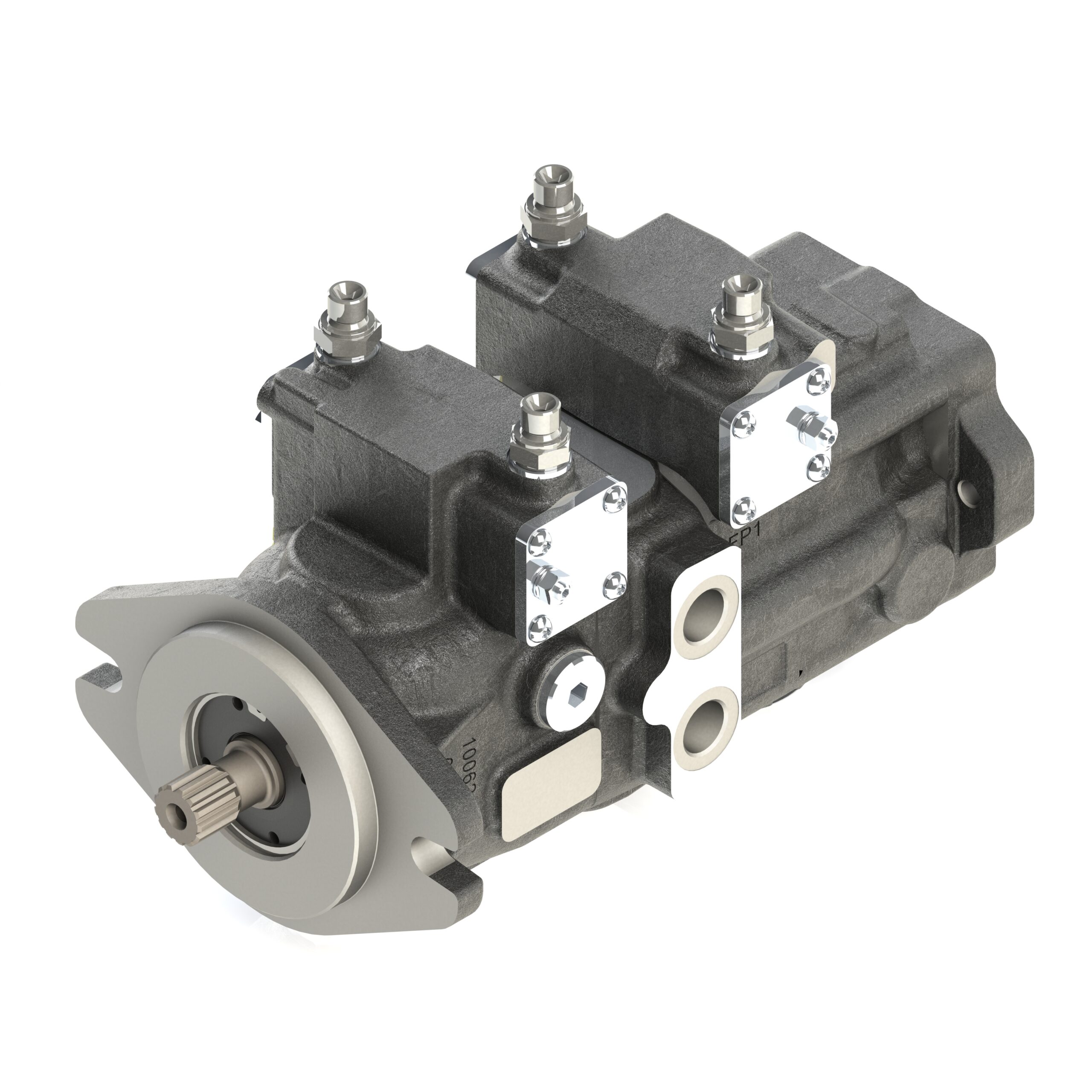

Axial Piston Pumps for Closed Loop System

Pmax: 480bar

Opition: wide range of options and controls, like hydraulic and electric automotive control

Displacement: 20-102 cc/rev

Pmax: 350 bar

Optional: speed sensor, flushing valve and brake

GEARPUMP1 2 0

Displacement: 0.16-77 cc/rev

Pmax: 250 bar

Optional: valvole

Wide range of valve to complete the system:

• On – Off Valve

• Proportional Valves

• Compact hydraulics

• Directional Valves and Remote controls

Joystick and pedals: wide range of hydraulic and electric joystick and pedals