Hydraulic systems are commonly used in fruit and vegetable picking equipment to facilitate efficient and gentle harvesting processes.

Here’s a detailed breakdown of the hydraulic components and their functions in the hydraulic circuit of fruit or vegetable picking machinery:

Hydraulic Circuit of Fruit or Vegetable Picking Equipment:

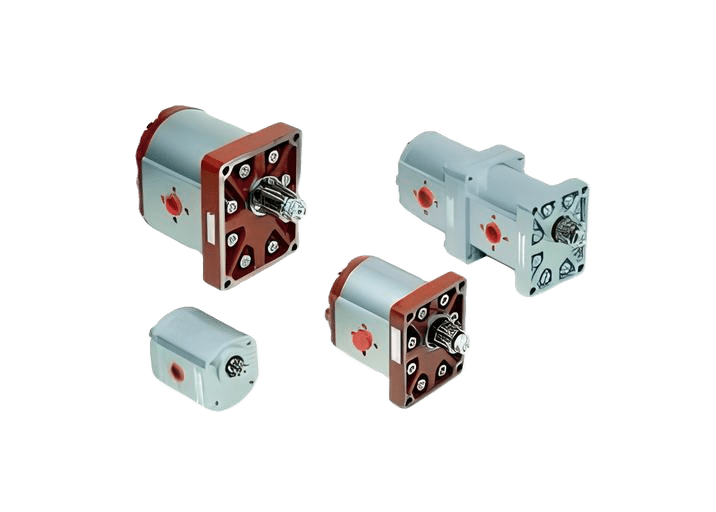

- Hydraulic Pump: The hydraulic pump generates the pressure needed to power the hydraulic functions of the picking equipment. It draws hydraulic fluid from the reservoir and pressurizes it for distribution.

- Hydraulic Fluid Reservoir: The reservoir stores hydraulic fluid, which is drawn by the pump. It ensures a consistent supply of fluid and helps manage temperature and air bubbles.

- Control Valves: Picking equipment is equipped with control valves that regulate the flow of hydraulic fluid to different components. These valves control the movement of arms, grippers, or cutting tools used for harvesting.

- Picking Arms or Grippers: Hydraulic cylinders power the movement of picking arms or grippers, allowing them to gently grasp or cut fruit or vegetables from the plants.

- Cutting Mechanisms: In some cases, hydraulic systems control cutting mechanisms such as blades or shears for cleanly severing fruits or vegetables from their stems.

- Articulating Arms: Some picking equipment may feature articulating arms that allow for precise positioning of the picking head. Hydraulic cylinders control the articulation of these arms for accurate picking.

- Fruit/Vegetable Collection Bins: Hydraulic systems may control the movement and positioning of collection bins, ensuring that the harvested produce is deposited smoothly into bins without damage.

- Sorting and Conveying: Hydraulic components can be used to control conveyors and sorting mechanisms that transport harvested produce to packing stations while removing debris and damaged items.

- Variable Speed Control: Advanced picking equipment may have variable speed control systems that adjust the speed of movement based on the type of fruit or vegetable being harvested, optimizing the picking process.

- Hydraulic Fluid Cooling: Hydraulic fluid cooling systems help maintain optimal temperatures during extended periods of operation, preventing overheating of hydraulic components.

- Gentle Handling: Hydraulic systems in fruit and vegetable picking equipment are designed to provide precise control, allowing for gentle and careful harvesting that minimizes damage to the produce.

- Position and Pressure Feedback: Sensors and feedback systems can be integrated into the hydraulic circuit to monitor the position of picking arms, grippers, and other components, ensuring accurate and consistent operation.

The specific hydraulic components and functions in fruit or vegetable picking equipment can vary depending on factors such as the type of produce, harvesting technique, and machinery design. The hydraulic system’s role is critical in enabling efficient and gentle harvesting, which is essential to preserving the quality of the harvested fruits or vegetables.

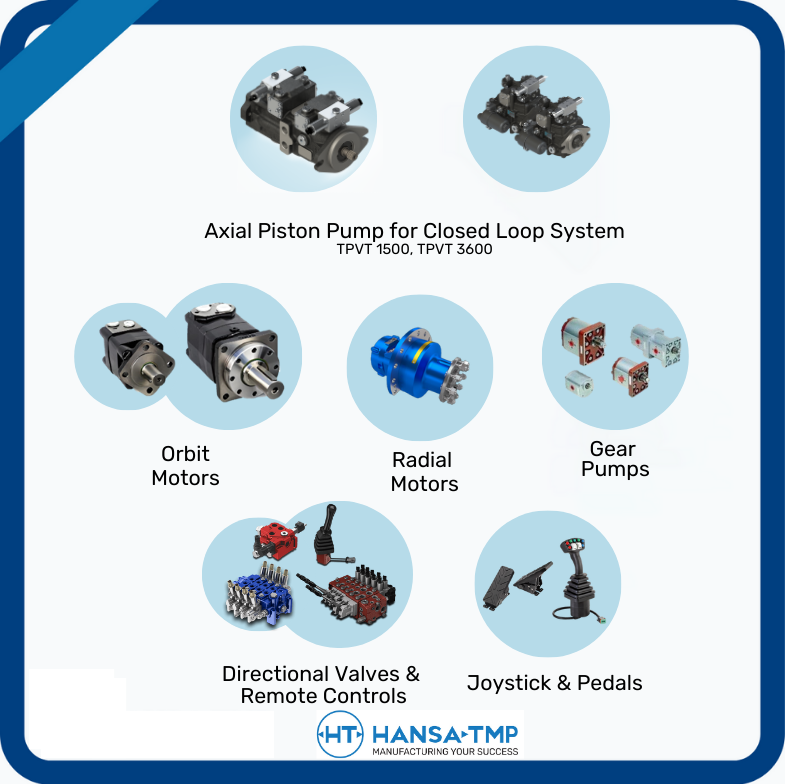

Details of the hydraulic system designed by HANSA TMP

HANSA TMP with its extensive experience in the field of hydraulics applied to construction machinery proposes an integrated solution.

The benefits of the system proposed by HANSA TMP are many:

- Compactness

- Reliability

- Reduction in consumption

- A single partner for on-board hydraulics

Product specifications

Axial Piston Pumps for Closed Loop System

Displacement: 6-130cc/rev

Pmax: 480bar

Opition: wide range of options and controls, like hydraulic and electric automotive control

Displacement: 260-565 cc/rev

Pmax: 450 bar

Optional: speed sensor, flushing valve and brake

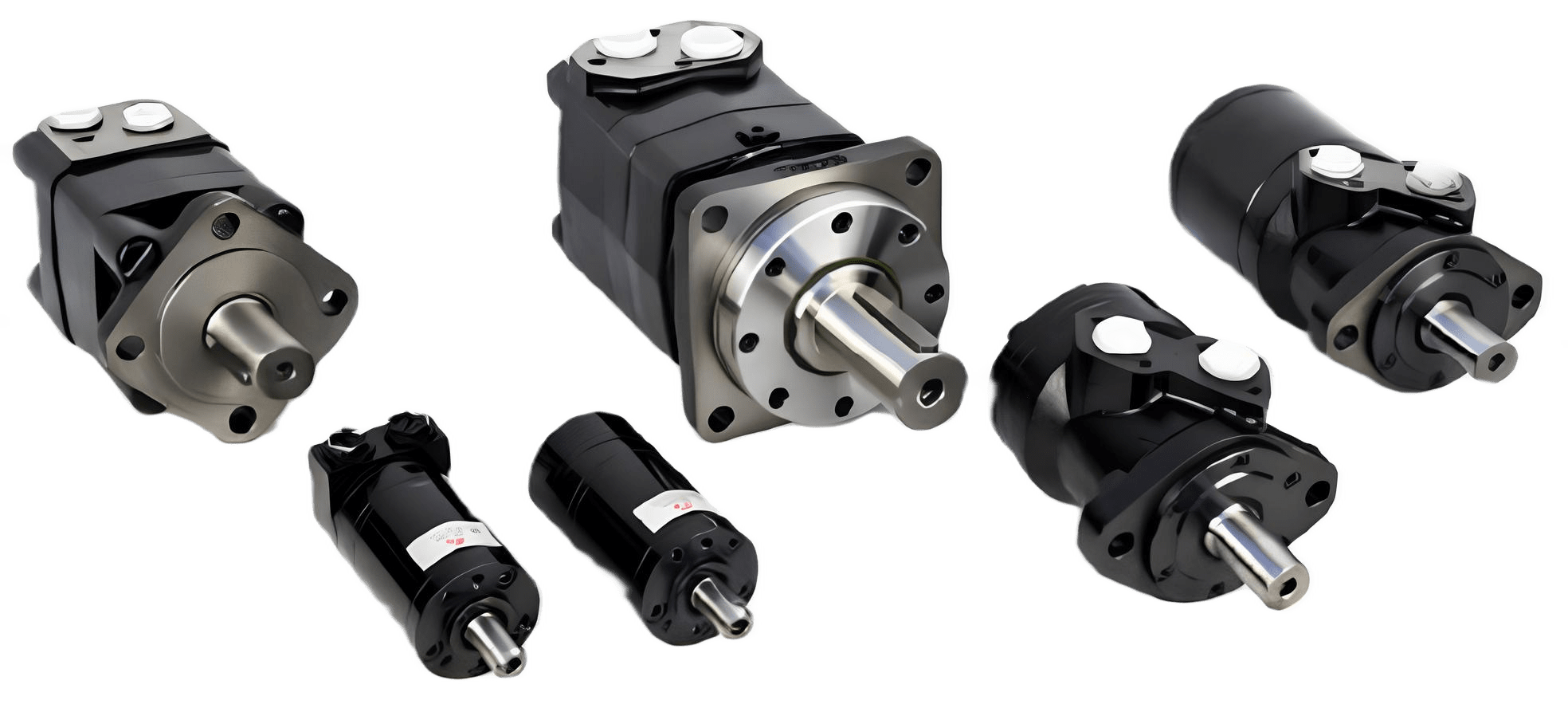

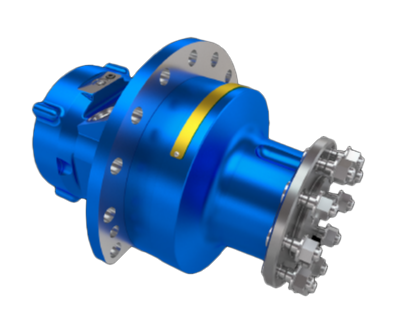

Orbit Motors: with spool valve, disk valve and with brake

Displacement: 8-1200 cc/rev

Pmax: 300 bar

Optional: brake

Pmax: 250 bar

Optional: valvole

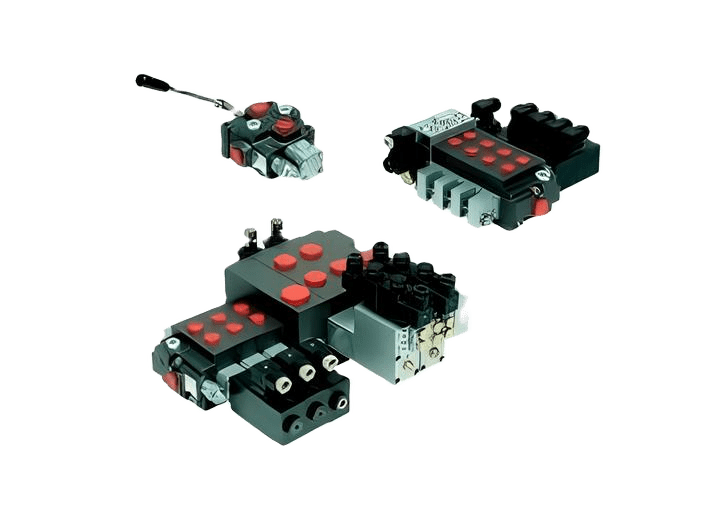

Wide range of valve to complete the system:

- On – Off Valve

- Proportional Valves

- Compact hydraulics

- Directional Valves and Remote controls

Joystick and pedals: wide range of hydraulic and electric joystick and pedals

Elettronica Controlli 1