Electrification is a process under development for all machines on road and off-road. Until now, traditional electric hybrid vehicles have combined internal combustion engine power plants with electric motors/ generators to propel the vehicle or capture its braking energy. In the same way as this, hydraulic hybrid vehicles couple hydrostatic transmissions and hydraulic accumulators to an internal combustion engine (ICE) to achieve the same tasks as their electrified counterparts.

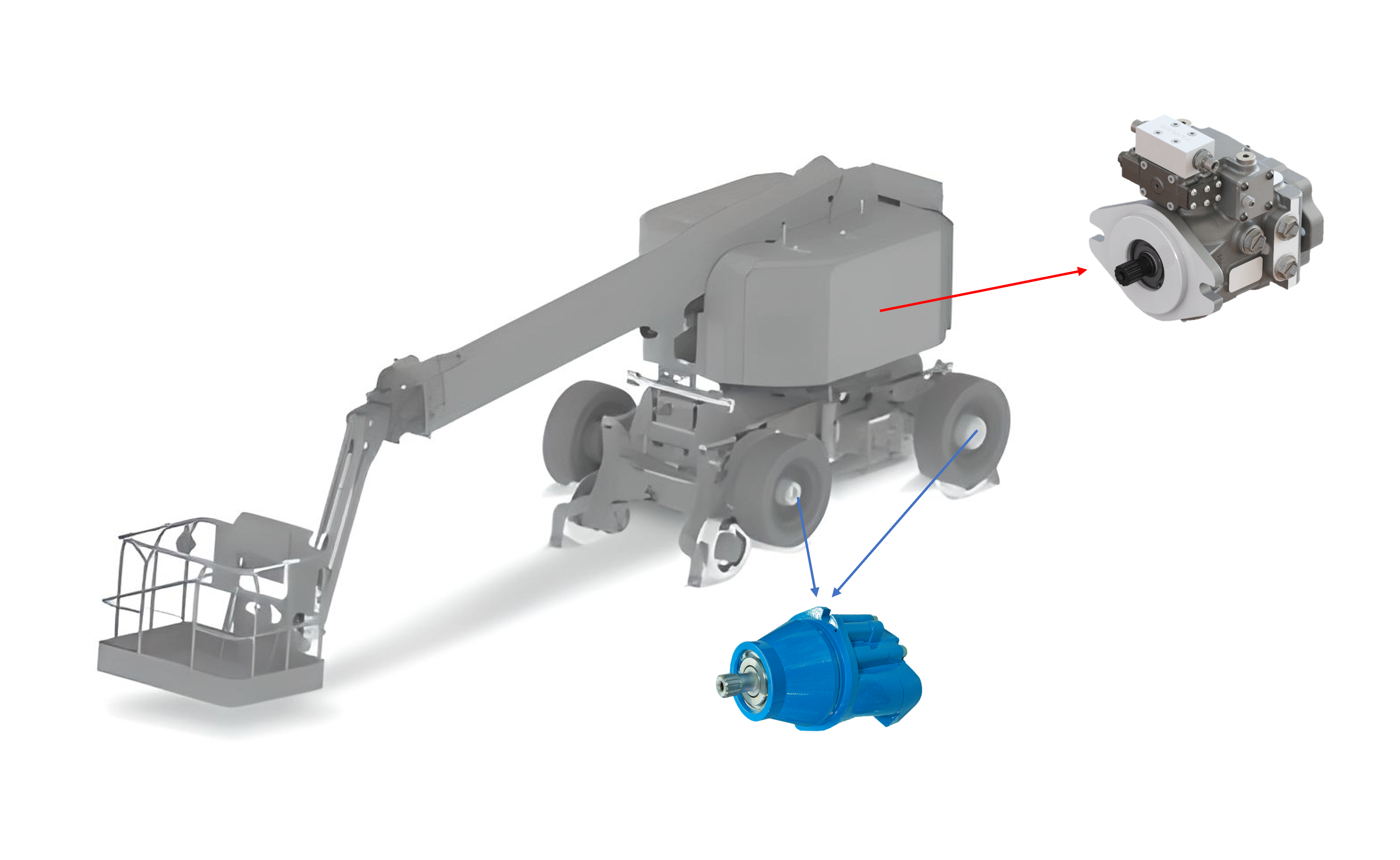

Complete hydraulic system

The transition process from endothermic to electric motor is at an advanced stage of development for applications on medium-sized machines and vehicles. For this kind of application, Hansa-TMP can provide a complete hydraulic system composed of electric motor, electronic control unit (ECU), inverter and batteries. In particular, the technology developed by Hansa-TMP on its TPV series of closed loop axial piston pumps can be used with both types of motors. Despite the small dimensions of the pumps, high performances and low levels of noise are ensured while working.

Resistance, precision and performance

The TPV 1500 in particular – both single and tandem – can work up to 24cc/rev and the new TPV 2500 can work from 6 to 38 cc/rev and up to 350bar. The back-to-back version ensures more resistance, greater precision and an increase in performance. Pumps are characterised by zero emissions and noises, high power density, high pressure, and compactness. According to the latest regulations on materials like cast iron and based on endurance tests, the design has been improved to facilitate the maintenance. Through all of this, the component is more reliable and functioning.

Both hydraulic and electrical controls can be assembled on the pumps. It depends mainly on the project of the application. The electrical control is easier to wire, on the other side the hydraulic one requires more time while assembling it.

Autonomous control

Pumps are available with a wide range of controls, especially the new electrical automotive one.

It is an ‘autonomous’ control for hydrostatic transmissions that allows the modulation of the displacement of the pump depending on the variation of the rpm. In this way, the pump can work autonomously. Otherwise, there are different types of hydraulic or proportional controls that

are available for remote regulation of the pump displacement by means of hydraulic or electric joysticks. Pumps are also available with integrated sensors for the control of the speed, of the angular position of the swashplate and of the oil pressure.

These sensors allow a complete remote control of the pump by an external electronic system.

Hansa-TMP’s closed loop axial piston pump can be integrated with a wide range of options: prearranged for connection with external filter, purge valve with screw by-pass, screw by-pass, filter with/ without clogging indicator, man on board, angle sensor, RPM sensor, pressure sensor, port threads and restrictor diameter.

Digital dashboard

To integrate and complete the system, Hansa-TMP can provide the digital dashboard: a touchscreen monitor (to set up and display the functional parameters) and an inching (to gradually reduce the displacement of the pump).

With the aim of satisfying the dynamism demanded by the market in terms of performance and the search for ever more technologically advanced solutions, Hansa-TMP is continuing to develop and integrate its product range to best meet this need, always maintaining high quality

standards.